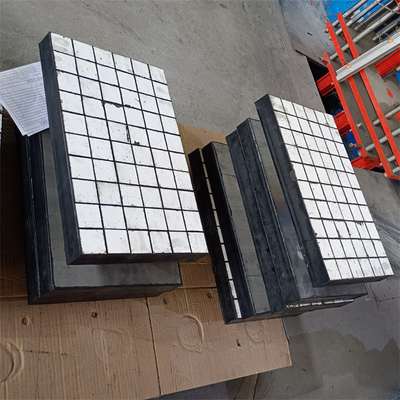

Anti Aggression Bolt On Rubber Ceramic Liner For Chute Hopper

Ceramic Wear Liner Description:

A ceramic wear liner is a type of protective lining used in industrial applications to protect equipment and surfaces from abrasive or corrosive materials. The liner is typically made of high-quality ceramics, such as alumina, zirconia, or silicon carbide, that offer excellent resistance to wear, impact, and high temperatures.

Ceramic Wear Liner selection chart:

|

Item

|

Description

|

Unit

|

Result

|

|

Alumina Ceramics

|

|

1

|

Alumina(Al2O3)

|

%

|

92 / 95

|

|

2

|

Desity

|

g/cm3

|

3.64

|

|

3

|

Water Absorption

|

%

|

≤0.01

|

|

4

|

Hardness

|

Mohs

|

9

|

|

Rubber

|

|

1

|

Material

|

|

NR, BR

|

|

2

|

Gravity

|

Tensile Strength

|

1.15

|

|

3

|

Tensile Strength

|

MPa

|

16 min

|

|

4

|

Elongation

|

%

|

400 min

|

|

5

|

Abrasion Loss

|

mm3

|

≤80

|

|

6

|

Aging coefficient (70ºCx48h)

|

|

0.87

|

|

Peeling Strength

|

|

1

|

Peeling strength between rubber & ceramic

|

KN/m

|

≥12

|

|

2

|

Peeling strength between rubber & steel

|

KN/m

|

≥12

|

Ceramic wear liner installed method:

| Bolt On |

Ceramic rubber liner with bolts, countersunk, etc |

| Bond on |

Ceramic rubber liner with cn bonding layer |

| Magnetic |

Ceramic rubber liner with magnets

|

Ceramic Wear Liner Features:

- Excellent wear resistant

- High-temperature resistance

- Corrosion resistance

- Customizable

- Easy installation

- Low maintenance

Ceramic Wear Liner Application:

Ceramic wear liner can also be widely used for serious abrasive environments, such as chute liners, cyclone liners, conveyor skirt liners, processing piping liners, hopper or silo liners, screen equipment liners in the industries including ,but not limited to:

♦ Coal Preparation Plants

♦ Coal Fired Power Stations

♦ Mineral Processing Plants

♦ Cement Plants

♦ Chemical Plants

♦ Steel & Iron Plants

♦ Railway Stations

♦ Ports

Why choose us:

1. Rich experience on production process of rubber ceramic wear liner

2. Strict quality control on rubber ceramic wear liner

3. Good delivery time

4. Custom shape rubber ceramic wear liner plate are available.

5. Excellent bonding between rubber and ceramic

We are a factory dedicated to producing ceramic wear liner and have been improving the properties of ceramics. We use high quality rubber to offer better impact resistance and high quality rubber can also help holding the ceramic tiles, no ceramic tiles falling.

We also use brand adhevise to ensure the bonding between ceramic and rubber.

Ceramic shapes can be cylinder, hexagonal, square, rectangular, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!