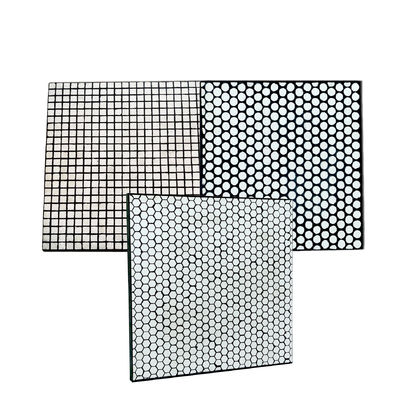

Wear Resistant Ceramic Wear Tiles 92% 95% Alumina Ceramic Liner And Pipe Linings

Ceramic Wear Tiles Description:

The alumina ceramic tiles are arranged in a specific pattern to provide maximum protection against wear and impact. They are known for their exceptional hardness and wear resistance, which make them ideal for use in harsh industrial environments.

Alumina ceramic liner is a type of protective lining used in industrial applications to protect equipment and surfaces from abrasive or corrosive materials. The liner is typically made of high-quality ceramics, such as alumina, zirconia, or silicon carbide, that offer excellent resistance to wear, impact, and high temperatures.

Ceramic Wear Tiles Specification:

| Specification (mm) |

Thickness of ceramic (mm) |

Thickness of rubber (mm) |

Thickness of steel backing plate |

Total thickness (mm) |

| 300x300x36 |

Φ21x21 |

9 |

6 |

36 |

| 300x300x50 |

Φ31x31 |

13 |

6 |

50 |

| 250x250x36 |

Φ21x21 |

9 |

6 |

36 |

| 250x250x50 |

Φ31x31 |

13 |

6 |

50 |

| 250x250x18(17.5x17.5x8) |

7 |

5 |

6 |

18 |

Ceramic Wear Tiles Features:

1. Excellent impact resistant

2. Excellent wear resistant

3. Excellent sound noise solution

4. Extend the service life of equipment

5. Cost effective

6. Reduce maintance and downtime

7. Customization accept

8. Rich experiences and strict QC ensures high quality

Ceramic Wear Tiles Application:

Alumina ceramic liners can be applied in various industrial applications where there is a need for good wear resistance and protection against abrasion, impact, and corrosion. Some of the common applications of ceramic rubber liners include:

1. Mining and mineral processing

2. Power generation

3. Chemical processing

4. Steel and cement

5. Waste management

Ceramic Wear Tiles Package:

Standard export packing, plywood pallet, no wood, no need fumigation

Pallet size: 1000*1000*620mm, Pallet weight: 1.2 tons

Pallet quantity for each 20GP container: 20~24 pallets

Why choose us:

1. We are a factory producing ceramic wear liners.

2. Proven quality

3. Standard and custom-made wear liners to fit your facility.

4. Excellent bonding between ceramic and rubber.

5. Extensive experience ensures high quality and consistency.

6. Custom ceramic rubber wear liners are available as per drawing and sample.

7. Strict QC/QA system, testing report will be issued to each purchase order.

We are a factory dedicated to producing ceramic wear liner and have been improving the properties of ceramics. We use high quality rubber to offer better impact resistance and high quality rubber can also help holding the ceramic tiles, no ceramic tiles falling.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!