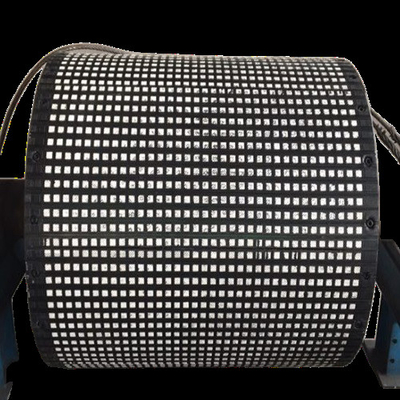

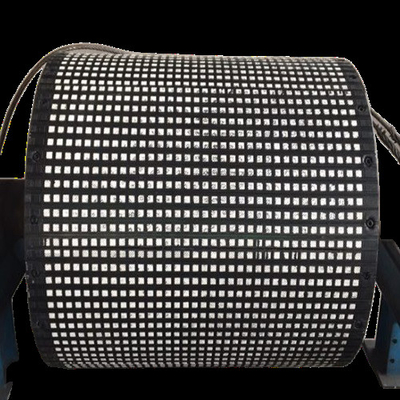

Product Description:

Alumina ceramics have high hardness and high wear resistance, which can better prevent belt slippage and protect drums and idlers. The rubber is made of styrene-butadiene rubber, which is tear-resistant and has good bonding performance, effectively preventing the ceramic block from falling off.

Features:

1.Reduce belt slippage

2.Extend belt and pulley life

3.Available in Natural Rubber and FRAS approved rubber

4.With CN bonding layer

Technical Parameters:

Performance of Ceramic, Rubber and Their Strength

Ceramic has a Mohs hardness of 9°, which is the highest among non-metals.

Rubber hardness is measured on the Shore A scale, ranging from 60 to 65.

The tensile strength of the materials should be ≥15 MPa. Elongation at breaking point should also exceed 300%.

Furthermore, the temperature range that it could adapt is -40℃ to 80℃ and the wear resistance index is ≤140 mm³. Finally, the peel strength should exceed 13MPa.

Applications:

Ceramic pulley lagging is commonly used in industries such as mining, cement, power generation, recycling, and bulk material handling, where reliable and efficient conveyor belt performance is crucial. By providing enhanced grip and reduced slippage, ceramic pulley lagging helps to improve productivity, reduce maintenance costs, and ensure safe and efficient material handling operations.

Packing and Shipping:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!