Product Description:

Ceramic Pulley Laggings

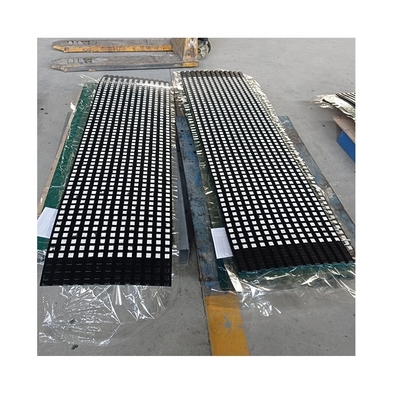

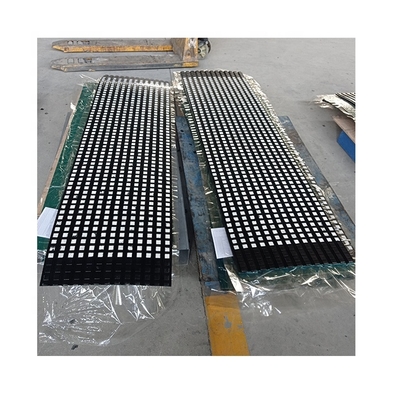

Ceramic pulley laggings are an increasingly popular solution to meet the demands of the most harsh conditions in material handling industries such as mining, cement, etc. Featuring a unique rubber matrix embedded with hard-wearing ceramic tiles or segments, ceramic lagging provides superior wear resistance and high hardness, while also reducing friction that could otherwise result in conveyor belt slippage. In this way, ceramic pulley laggings help to improve the overall performance of conveyor systems, as they increase the frictional grip between the pulley and the conveyor belt, resulting in a better traction rate and improved efficiency. The ceramic tiles used in the laggings are generally comprised of high-density alumina and/or specialty ceramics, which provide enhanced performance and long-term durability.

Features:

- Product Name: Ceramic Pulley Lagging

- Hardness: Mohs 9

- Color: White,Black

- Use life: Over 2 Years

- Abrasion Resistance: High Abrasion Resistant

- Features:

- Wear abraision ceramic conveyor pulley lagging

- Ceramic pulley lagging for drive rollers

- Vulcanized ceramic conveyor pulley lagging

Technical Parameters:

Ceramic Hardness

Ceramic hardness is measured using the Mohs Scale and is rated 9°

Rubber Hardness

Rubber hardness is measured using the Shore A Scale and is rated between 60-65

Tensile Strength

Tensile strength indicates the maximum stress that a material can be subjected to before breaking. According to our reading the material has a tensile strength of ≥15 MPa.

Elongation at Break

Elongation at Break is the measure of the amount that the material can stretch before breaking. The material has an elongation at break of ≥300%

Temperature Range

Temperature range is the range of temperature that the material can withstand without damage or deformation. The material can withstand a temperature of -40℃ to 80℃.

Wear Resistance Index

Wear Resistance Index measures how the material resist wear when it is subjected to abrasion. The material has a wear resistance index of ≤140 mm³.

Peel Strength

Peel Strength measures the maximum force per unit width of a material when two sides are pulled in opposite directions. The material has a peel strength of ≥13 MPa.

Applications:

Debon provides the premium ceramic pulley lagging solution for the conveyor industry. Our ceramic pulley lagging is used to improve pulley performance, reduce belt slippage and extend pulley life. It is made of ceramic tiles that are 35% thicker than standard lagging, offering superior wear abrasion and protection to any pulley. The square ceramic lagging is available in various thicknesses, 12mm, 15mm, 20mm and 25mm, and can be installed with either a cold bonding or CN bonding layer. It is designed to offer the maximum grip, and its long-lasting use life of over two years ensures a secure, reliable and durable performance.

Packing and Shipping:

Ceramic Pulley Lagging Packaging and Shipping:

The Ceramic Pulley Lagging will be carefully packaged and shipped in a cardboard box to ensure it reaches its destination in perfect condition. The box will be lined with foam to protect the product from any shocks or impacts during transit. The product will be clearly labeled with a shipping label that includes all of the necessary information, such as the shipping address and estimated delivery time.

FAQ:

- Q: What is Ceramic Pulley Lagging?

- A: Ceramic Pulley Lagging is a product used to cover the pulley surface and increase friction, providing a better grip and reducing wear.

- Q: What brand is Debon Ceramic Pulley Lagging?

- A: Debon Ceramic Pulley Lagging is a product of the Debon brand, with model number DB-TC.

- Q: Where is Debon Ceramic Pulley Lagging made?

- A: Debon Ceramic Pulley Lagging is made in JIAOZUO, HENAN, CHINA.

- Q: What are the features of Debon Ceramic Pulley Lagging?

- A: Debon Ceramic Pulley Lagging has many features, including increased grip, reducing wear, and improved performance.

- Q: What are the benefits of using Debon Ceramic Pulley Lagging?

- A: Debon Ceramic Pulley Lagging provides a number of benefits, including improved traction and a longer service life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!