Product Description:

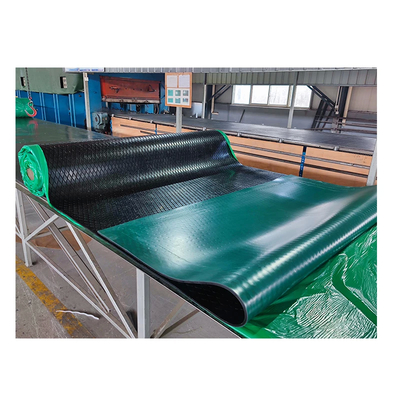

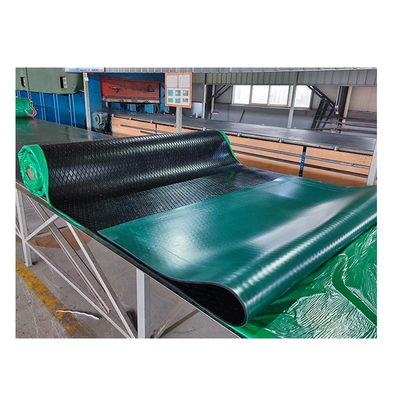

Conveyor Pulley Lagging is an essential part of a conveyor system that helps to reduce the friction and wear between the belt and pulley. It is designed to increase the life of the pulley and reduce the downtime and maintenance costs. It is available in a variety of surface types, such as flat, diamond, or ceramic tiles, and thicknesses ranging from 10mm to 20mm. It is suitable for applications in mining, cement, aggregate, and bulk material handling, and is resistant to temperatures ranging from -40°C to 80°C. We offer Rubber Lagging and Ceramic Lagging solutions for drum pulley rubber lagging, ceramic rubber wear lagging, and ceramic rubber lagging to meet the needs of our customers.

Features:

- Product Name: Conveyor Pulley Lagging

- Application: Mining, Cement, Aggregate, And Bulk Material Handling

- Resistance: Abrasion; Wear

- Thickness: 10mm;12mm;15mm;20mm;

- Type: Rubber Lagging; Ceramic Lagging

- Temperature: -40~80℃

- Special Feature: Diamond rubber wear lagging

- Usage: Pulley lagging, Drive Pulley lagging

Applications:

Conveyor Pulley Lagging from Debon is a premium product designed to provide superior wear protection for conveyor belts and pulleys. It is made of a high-quality SBR rubber compound that is designed to resist abrasion, impact and corrosion. The product is available in a variety of thicknesses, surface finishes and lengths to meet the needs of any application. It is also certified ISO9001, ISO14001 and SGS for quality assurance.

The rubber pulley lagging is manufactured with a cold bonding layer to ensure a strong bond to the pulley. It has a temperature rating of -40°C to 80°C and can be used in a variety of conditions. It is available in 10mm, 12mm, 15mm and 20mm thicknesses with either a flat, diamond or ceramic tile surface finish. It is also available in up to 10m lengths or can be customized to meet the specific requirements of the application.

The product is designed for superior wear resistance and extended service life. It is suitable for use with SBR rubber pulley lagging, ceramic rubber wear lagging and rubber wear resistant lagging. It is offered at a competitive price and has a minimum order quantity of 1 pc. Delivery is usually within 7-15 working days and payment terms include T/T, L/C, Western Union, etc. Debon's supply ability is up to 10,000 pcs per month.

Support and Services:

Technical Support and Service for Conveyor Pulley Lagging

Conveyor pulley lagging provides extended service life and improved performance of conveyor systems, resulting in lower costs of operation. To ensure that your conveyor pulley lagging is working at its best, we offer technical support and service.

We can help you choose the right product for your application, explain the installation and maintenance process, and answer any questions you may have. We also provide on-site installation and repair services as well as regular maintenance inspections.

If you are experiencing any problems with your conveyor pulley lagging, our technicians can diagnose and repair any issues you may have. Our experienced technicians are also available to provide troubleshooting and advice on how to maintain your lagging in top condition.

For any technical support and service related to conveyor pulley lagging, please contact us at [EMAIL OR PHONE NUMBER].

Packing and Shipping:

Packaging and Shipping for Conveyor Pulley Lagging:

Conveyor Pulley Lagging is carefully packaged in corrugated boxes lined with foam to ensure safe delivery. The boxes should be labeled with the shipment details and weighed prior to shipping. The boxes should then be sent to the appropriate destination via the most suitable shipping method.

FAQ:

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!