Alumina Ceramic Liner Welded Ceramic Lining New Ceramics For Mineral

Alumina Ceamic Liner Description:

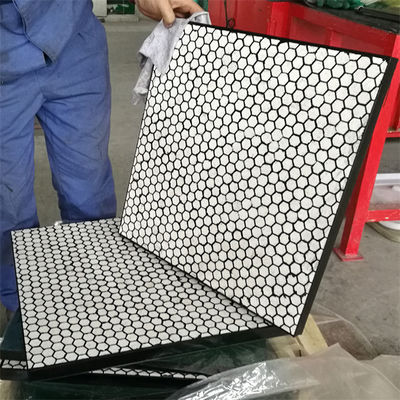

Alumina ceramic liner is a type of wear-resistant lining material used to protect industrial equipment from abrasion, impact, and corrosion. It is made of high-density alumina ceramic tiles or panels that are bonded to a substrate such as steel or rubber.

The alumina ceramic tiles are arranged in a specific pattern to provide maximum protection against wear and impact. They are known for their exceptional hardness and wear resistance, which make them ideal for use in harsh industrial environments.

Alumina Ceramic Liner Specification:

| Item |

Description |

Unit |

Result |

| Alumina Ceramic Wear Tiles |

| 1 |

Alumina (Al2O3) |

% |

92 , 95 |

| 2 |

Density |

g/cm3 |

3.64 |

| 3 |

Water absorption |

% |

≤0.01 |

| 4 |

Hardness |

Mohs |

9 |

| Rubber |

| 1 |

Material |

|

NR or SBR |

| 2 |

Gravity |

g/cm3 |

1.15 |

| 3 |

Tensile Strength |

MPa |

15 min. |

| 4 |

Hardness |

Shore A |

55+/-5 |

| 5 |

Elongation |

% |

400 min |

| 6 |

Abrasion Loss |

mm3 |

≤90 |

| 7 |

Aging Coefficient (70°C x 48h) |

% |

8.7 |

Alumina Ceramic Liner Features:

- High hardness for protecting equipment from abrasion and impact

- Highly resistant to chemicals and corrosion

- Temperature resistance, making it ideal for use in applications with elevated temperatures.

- Customizable,can be customized to fit almost any shape or size of equipment

- Low friction,helps to reduce the loss of materials and energy during transportation

- Long lifespan,reducing maintenance costs and downtime.

Alumina Ceramic Liner Application:

Alumina ceramic wear liners are commonly used in industries such as mining, cement production, power generation, and steel manufacturing, where equipment is subjected to extreme conditions and heavy wear.

Alumina Ceramic Liner Package:

Standard export packing, plywood pallet, no wood, no need fumigation

Pallet size: 1000*1000*620mm, Pallet weight: 1.2 tons

Pallet quantity for each 20GP container: 20~24 pallets

Why choose us:

We are professional manufacturer of ceramic wear liner and industry wear resistant products. We produce various kinds of belt cleaner, belt sealing skirting, pulley lagging, ceramic rubber liner,etc, to meet different applications, custom size and structure are available.

We will be your reliable partner and supplier.

1. Over 20 years experience in wear products and conveyor accessories.

2. Over 10 years experience in exporting, UK, France, Chile, Canada, USA, Finland, Australia, Russia, Indonesia, Thailand, etc.

3. SGS audited supplier.

4. ISO9001:2015 certified factory.

5. Strict QC/QA makes sure high quality and consistency.

We are a factory dedicated to producing ceramic wear liner and have been improving the properties of ceramics. We use high quality rubber to offer better impact resistance and high quality rubber can also help holding the ceramic tiles, no ceramic tiles falling.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!