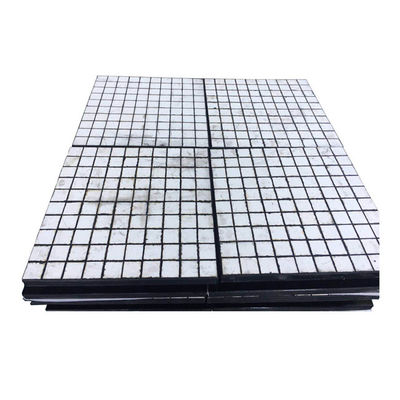

92% AI2O3 Alumina Ceramic Liner Chute Rubber Lining For Mining

Alumina Ceramic Liner Description:

Alumina ceramic liner is a type of wear-resistant lining material used to protect industrial equipment from abrasion, impact, and corrosion. It is made of high-density alumina ceramic tiles or panels that are bonded to a substrate such as steel or rubber.

The alumina ceramic tiles are arranged in a specific pattern to provide maximum protection against wear and impact. They are known for their exceptional hardness and wear resistance, which make them ideal for use in harsh industrial environments.

Alumina ceramic liner is a durable and long-lasting solution for protecting equipment and reducing maintenance costs in challenging industrial environments.

Alumina Ceramic Liner installed method:

| Bolt On |

Ceramic rubber liner with bolts, countersunk, etc |

| Bond on |

Ceramic rubber liner with cn bonding layer |

| Magnetic |

Ceramic rubber liner with magnets |

Alumina Ceramic Liner selection chart:

| Specification (mm) |

Thickness of ceramic (mm) |

Thickness of rubber (mm) |

Thickness of steel backing plate |

Total thickness (mm) |

| 300x300x36 |

Φ21x21 |

9 |

6 |

36 |

| 300x300x50 |

Φ31x31 |

13 |

6 |

50 |

| 250x250x36 |

Φ21x21 |

9 |

6 |

36 |

| 250x250x50 |

Φ31x31 |

13 |

6 |

50 |

| 250x250x18(17.5x17.5x8) |

7 |

5 |

6 |

18 |

Alumina Ceramic Liner Features:

1. High alumina ceramic offers excellent wear resistant

2. Rubber layer prevents ceramic tiles breakage

3. available with stud bolt and weldable installation methods or cn bonding layer

4. Various shape and size of ceramic, bricks, cylindrical, etc.

5. The magnets embedded in the rubber backing allow for quick and easy installation and removal of the ceramic tiles

Alumina Ceramic Liner Application:

-

Mining industry: Alumina ceramic liner is used in mining equipment such as chutes, hoppers, and conveyors, where it provides effective protection against abrasion and impact.

-

Cement industry: Alumina ceramic liner is used in cement plants to protect equipment from the abrasive effects of raw materials and to improve the efficiency of material handling.

-

Power generation industry: Alumina ceramic liner is used in coal-fired power plants to protect equipment such as pulverizers, ash handling systems, and scrubbers from wear and erosion.

-

Steel industry: Alumina ceramic liner is used in steel mills to line blast furnace hoppers, hot metal cars, and other equipment that is exposed to high temperatures and abrasion.

-

Chemical industry: Alumina ceramic liner is used in chemical processing equipment such as reactors, pipes, and tanks, where it provides effective protection against corrosion and erosion.

Alumina Ceramic Liner Package:

Standard export packing, plywood pallet, no wood, no need fumigation

Pallet size: 1000*1000*620mm, Pallet weight: 1.2 tons

Pallet quantity for each 20GP container: 20~24 pallets

Why choose us:

1. Ceramic wear liner manufacturer.

2. Reliable factory with extensive experience.

3. High quality and consistency

4. ISO9001, ISO45001, ISO14001 certified factory.

We also use brand adhevise to ensure the bonding between ceramic and rubber.

Ceramic shapes can be cylinder, hexagonal, square, rectangular, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!