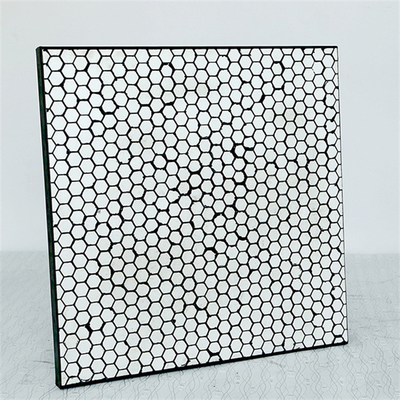

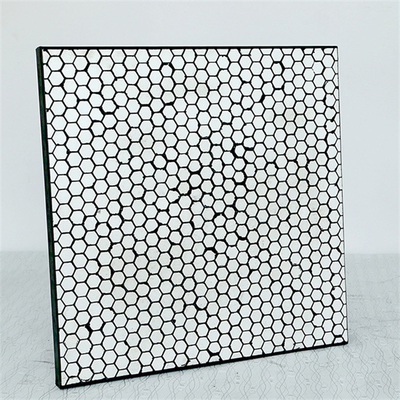

92% Alumina Ceramic Tiles Liners With Strong Magnet For Mining Industry

Alumina Ceramic Liner Description:

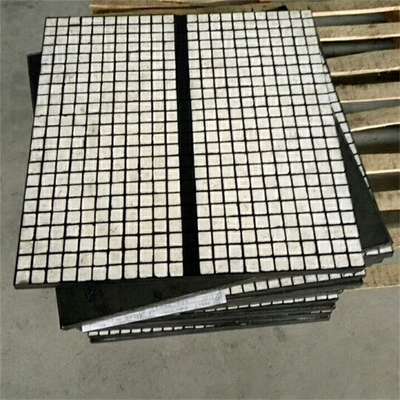

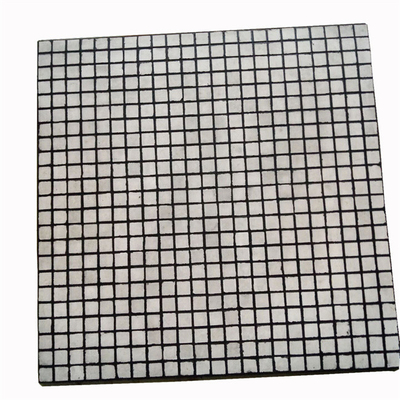

Alumina ceramic liner is a type of wear-resistant lining material used to protect industrial equipment from abrasion, impact, and corrosion. It is made of high-density alumina ceramic tiles or panels that are bonded to a substrate such as steel or rubber.

The alumina ceramic tiles are arranged in a specific pattern to provide maximum protection against wear and impact. They are known for their exceptional hardness and wear resistance, which make them ideal for use in harsh industrial environments.

Alumina Ceramic Liner Specification:

| Item |

Description |

Unit |

Result |

| Alumina Ceramic Wear Tiles |

| 1 |

Alumina (Al2O3) |

% |

92 , 95 |

| 2 |

Density |

g/cm3 |

3.64 |

| 3 |

Water absorption |

% |

≤0.01 |

| 4 |

Hardness |

Mohs |

9 |

| Rubber |

| 1 |

Material |

|

NR or SBR |

| 2 |

Gravity |

g/cm3 |

1.15 |

| 3 |

Tensile Strength |

MPa |

15 min. |

| 4 |

Hardness |

Shore A |

55+/-5 |

| 5 |

Elongation |

% |

400 min |

| 6 |

Abrasion Loss |

mm3 |

≤90 |

| 7 |

Aging Coefficient (70°C x 48h) |

% |

8.7 |

Alumina Ceramic Liner Features:

1. High alumina ceramic offers excellent wear resistant

2. Rubber layer prevents ceramic tiles breakage

3. available with stud bolt and weldable installation methods or cn bonding layer

4. Various shape and size of ceramic, bricks, cylindrical, etc.

5. The magnets embedded in the rubber backing allow for quick and easy installation and removal of the ceramic tiles

Alumina Ceramic Liner Application:

-

Mining industry

-

Cement industry

-

Power generation industry

-

Steel industry

-

Chemical industry

-

Military industry

Why choose us:

1. Production experience:factory since 1996, mature production line, advanced facility, Strict QC.

2. Export experience:export since 2008, to over 50 countries.

3. Quality control:Conveyor belt scraper cleaner is one of our best sellers.We inspect each batch of our delivery. We have our laboratory for testing the hardness, dimensions,etc.

4. Quick delivery time:generally delivery can be made within one week.

We are a factory dedicated to producing ceramic wear liner and have been improving the properties of ceramics. We use high quality rubber to offer better impact resistance and high quality rubber can also help holding the ceramic tiles, no ceramic tiles falling.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!